Ozone Treatment Installation Manual

PURE WATER™

Ozone Water Treatment System

Model PW 9000

INSTALLATION MANUAL

When installing this electrical equipment, basic safety precautions should be followed, including:

1. READING AND FOLLOWING ALL INSTRUCTIONS.

2. Do not breathe the ozone gas that exits the ozone generator for an extended period of

time.

3. Do not breathe the accumulated ozone gas within the water holding tank for an extended

period of time. Before working inside tank, turn off ozone generator and fully ventilate

tank. Note: Ozone is heavier than air.

4. Connect the ozone generator to a properly grounded, grounding type receptacle only.

Do not bury power cord nor allow cord to be in contact with standing water.

WARNING - To reduce the risk of electrical shock, replace power supply cord immediately

if it should become damaged.

5. WARNING - To reduce the risk of electrical shock, disconnect power supply before

servicing ozone generator.

6. The ozone generator must be mounted vertically.

7. The ozone generator creates heat and must be installed with adequate ventilation

8. Install the unit in compliance with all national and local codes.

9. SAVE THESE INSTRUCTIONS.

Congratulations. Your new ozone water treatment system is the latest in clean water technology. The system will continuously ozonate (oxidize), circulate and filter the entire contents of your holding tank, providing you with fresh, clean water for your home. The system is designed to remove Iron, Manganese, Hydrogen Sulfide (rotten egg odor), Tannins, raise Acid PH to the non-acidic range, kill bacteria, remove color, taste odor, make your water feel softer, and increase the dissolved oxygen content of your water.

OZONE: WHAT IS IT?

Ozone (O3), one of nature`s basic elements, is a very powerful disinfecting and deodorizing gas consisting of oxygen (O2) with an extra oxygen atom attached, therefore becoming ozone (O3). When oxygen in the air is exposed to high intensity ultraviolet rays, ozone is created (such as our sun creating the ozone layer surrounding the Earth). When ozone does its job, it oxidizes by giving up and attaching its extra oxygen atom to anything that can be oxidized. Once this process occurs, the ozone molecule becomes pure oxygen (O3 - O = O2). Thus, the only by-product of ozone is pure oxygen. In fact, ozone reverts to oxygen quite naturally and rapidly. The half life of ozone in air is on the order of hours and the order of minutes when dissolved in water. Additionally, ozone dissolves over 12 times more rapidly into water than pure oxygen. It then reverts to oxygen, providing hundreds of times more dissolved oxygen in your water than could otherwise be possible.

HOW THE SYSTEM WORKS

The system consists of three major components: Ozone Generator, In-Line Mixer, and Filter Module. The ozone generator plugs into a standard receptacle (115v-60hz). It has an air pump which provides compressed air into an Ultraviolet Ozone producing lamp assembly, thus producing compressed ozone. The mixer installs into the water feed pipe to your holding tank. The ozone gas is routed from the ozone generator, through the mixer, to the filter module. When your well pump is pumping water into your tank, the mixer automatically diverts and mixes the ozone gas into the incoming well water before it enters the tank. When your well pump is not pumping water into your tank, all of the ozone gas is directed to the inside of your tank for 24 hours a day, nonstop purification!

The filter module hangs underneath the water inside your holding tank. It includes a 100 square foot filter and a lift pipe with a diffuser (bubble maker). The ozone gas from the generator is fed to the filter module diffuser, which makes millions of tiny ozone saturated bubbles. These bubbles rise up the filter module lift pipe, mixing the ozone with the water and drawing water through the filter at the rate of approx. 10 gallons per minute. As the ozone saturated bubbles exit the lift pipe, the bubbles rise up throughout your holding tank, thus continuing the ozone/water absorption process and circulating the contents of your holding tank.

HOLDING TANK SIZE

One PW 9000 system is designed to purify the water in a tank of up to 10,000 gallons with normal contaminant levels. Larger tanks will require multiple systems. As a rule, the maximum water usage should never exceed 25% of the tank capacity in a 24 hour period. A typical family of 4 uses between 500-600 gallons per day. This would require at least 2500 gallon holding tank.

FILTER MODULE INSTALLATION

PREPARE THE FILTER MODULE FOR INSTALLATION INTO THE TANK:

1. Attach the handle/diffuser assembly to the filter top by feeding the diffuser hose down into the filter module lift pipe and attaching the quick disconnect.

1. Attach the handle/diffuser assembly to the filter top by feeding the diffuser hose down into the filter module lift pipe and attaching the quick disconnect.

2. Attach the stainless steel chain to the filter module by crimping the end link on to the center link of the chain handle.

3. Connect the Neoprene tubing (dull black rubber like hose) to the barb located on top of the filter module handle. Using the black plastic ties provided, gently tie the Neoprene hose at one foot intervals to the stainless steel chain. Do not over tighten the plastic ties as this will crush the hose and reduce ozone flow.

PREPARE THE TANK FOR INSTALLATION OF THE FILTER MODULE:

1. Drill a 1/4 inch hole through the top of the tank, approximately 4`` behind the manway. Reaching through the manway, insert the 1/4`` eyebolt with a fender washer through the 1/4`` hole. Next, on the outside of the tank, secure the eyebolt in place with another fender washer and nut.

2. On the side of the manway nearest the eyebolt, drill a 5/16 inch hole. This hole will later be used for routing the glossy black PVC tubing into the tank.

IMPORTANT: WHEN INSTALLING FILTER, THE BOTTOM OF THE FILTER MODULE MUST NEVER BE INSTALLED MORE THAN 8 FEET BELOW THE HIGHEST WATER LEVEL IN TANK. IN ORDER TO prevent stirring up of sediment, do not install filter module closer than 6`` from the bottom of tank.

3. Slowly lower the filter module down into the water. For deep tanks with water depths of 9 feet or more, position the bottom of the filter module no more than 8 feet below the highest level in tank. For shallow tank with water depths less than 8-1/2 feet, lower the filter module down into the tank until it touches the bottom and pull back up 6``.

4. Estimate length of chain needed to hang filter at proper height. Open link of chain at desired length and remove excess chain. Attach open link to eyebolt and crimp shut..

5. Inside the tank, attach the black glossy PVC hose from the ozone generator to the Neoprene hose which runs down the filter module. Use the black 90 degree tubing connector to make this connection. Discard any excess hose.

MIXER INSTALLATION

The mixer installs into the water feed pipe to your tank. For above ground tanks, the mixer should be installed at about the same vertical level as the filter module ( the bottom of the mixer should be at about the same level as the bottom of the filter module). For underground tanks, the mixer can be mounted anywhere above the ground, in any orientation.

The mixer has a 1`` PVC slip inlet at the bottom and a 1-1/2`` slip outlet at the top. To maximize the effectiveness of the mixer, a 1-1/2`` pipe should be run from the top of the mixer, vertically up the side of the tank, where it connects to the tank inlet fitting. If this is not possible, a 3-4 foot section of a 1-1/2`` pipe should be used before reducing back down to the existing inlet pipe. This will provide a ``mixing chamber`` for the ozone gas.

GLUE THE MIXER IN PLACE IN THE WELL WATER FEED LINE:

1. Determine vertical location of the mixer.

2. Cut the water pipe in appropriate location. Using PVC fittings, glue the water feed pipe from the well to the bottom input of the mixer.

NOTE: BE SURE THE MIXER IS COMPLETELY POSITIONED WITH THE ARROW ON THE BYPASS CHECK VALVE POINTING IN THE DIRECTION OF WATER FLOW. DO NOT REMOVE BLACK TIES ON MIXER ASSEMBLY.

3. Using appropriate PVC fittings, install 1-1/2`` PVC pipe from the top of the mixer to the tank inlet fitting.

Ozone hose installation:

1. Using the glossy black PVC tubing, connect one end to the top 0 PSI (white) check valve on the mixer assembly. (see figure 3A) Next, route the tubing up from the mixer assembly, along the inlet pipe and in through the 5/16`` hole previously drilled in the side of the manway. Inside the tank, cut the black glossy PVC tubing to length and connect it to the 90 degree connector. Use the black plastic ties to secure the PVC tubing to the inlet pipe. NOTE: If it is cold outside, heating the PVC tubing with a match will make it easier to slip onto the barb fittings.

2. Connect the 6 PSI (red) check valve hose to the venturi.

FREEZE PROTECTION:

The mixer assembly is subject to freezing as is the water feed pipe from the well. In freezing climates, insulate thoroughly. Use the "heat tape" in severe climates.

OZONE GENERATOR INSTALLATION

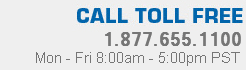

The ozone generator can be mounted up to 200 feet from the holding tank. 50 feet of black glossy PVC tubing is supplied which is more than adequate for most installations. Consult American Tank Co. if additional tubing and connectors are needed.

The generator construction is rain tight and can be mounted indoors or outdoors. Good ventilation is requires since the generator creates heat.

1. Remove the ozone generator lid.

2. Mount the ozone generator to a solid vertical surface with the 3 screws supplied. Two screws are used for the hanging tabs, and one for the 1/4`` hole in the back of the generator.

3. Write installation date on the sticker located on the inside of the generator lid.

4. Route the glossy black PVC tubing from the ozone generator to the lower 0 PSI (white) check valve on the mixer assembly. Be sure to route the tubing so it will not become accidentally damaged.

5. Plug the ozone generator into a properly grounded, grounding type receptacle. Use a waterproof receptacle if installed indoors.

STARTING UP YOUR SYSTEM

Recheck your installation to verify that it is correct. Turn the ozone generator on. You should hear a faint hum coming from the air pump. A faint blue-green glow should be visible through the small plastic lens on the outside of the generator. This indicates the UV lamp assembly is working and producing ozone.

NOTE: The UV lamp assembly may not fire up immediately if the ambient temperature is below 40 degrees F. The UV lamp assembly may never fire in extreme cold.

Looking through the manway, verify that there is a full pattern of bubbles rising from the filter module. This may take a few seconds to develop since the entire ozone tubing system must be pressurized. Now turn your well pump on. The bubble pattern inside the tank should decrease or stop completely. This indicates that the ozone gas is being correctly diverted to the mixer assembly. If you see no change in the bubble pattern in the tank, recheck your installation and make sure the ozone tubing is correctly installed and the mixer is installed with the flow arrows pointing in the direction of water flow.

If the installation is correct, it is possible that your well pump cannot create enough pressure to fully activate the mixer assembly. With the well pump turned on, pull off the black Neoprene hose from the venturi barb indicating that the mixer is working. Reinstall the neoprene tubing.

If no suction is detected, check for debris in the mixer assembly. The mixer bypass valve is factory set to 15 PSI. If your well pump cannot produce more than 15 PSI, the water flow in your tank will all pass through the venturi thus reducing your flow rate. This is no cause for alarm as reducing the water flow rate will not harm your well pump.

MAINTENANCE

Regular cleaning of your system`s filter and diffuser is important to keep the system operating at peak efficiency.

WHEN TO CLEAN FILTER

There appears to be a natural tendency to clean the filter more often than required. Actually, a slightly dirty filter will filter the water better than a new filter. The filter element will also filter out finer particulates once it has been used for awhile. This is referred to as "seasoning" the filter.

The time between filter cleanings will vary according to the severity and type of water problems, the condition of your holding tank prior to the system installation, and the daily amount of water usage.

To clean the filter, it is only necessary to hose the collected debris off the filter pleats - it is not necessary to scrub the pleat material or use any cleaning agents. The pleats will stain over time and will not become white when cleaned. This is normal and will not affect the function of the filter.

Use the following method to determine the cleaning interval for your filter:

1. After initial startup, perform the first filter cleaning in 10 to 14 days. If the filter is not "loaded" with particulates, clean again in 30 days. A "loaded" filter is defined as having more than 1/2 of the filter pleat depth filled with particulates. If the filter is not loaded at the 30 day cleaning, you can then set your cleaning schedule to every 60 days. If not loaded in 60 days you can extend the cleaning schedule to every 90 days. In no case should the filter cleaning interval exceed 90 days.

2. If the filters are loaded at the initial 10-14 day cleaning, continue cleaning at 2 week intervals until the filters are no longer loaded. This biweekly cleaning will be required if your tank has a lot of "growth" or deposits on the tank walls. The water treatment system will remove this growth off the tank walls, and your tank will each a point of stabilization. Once your tank has stabilized, extend your cleaning interval to 30 days. If the filters are not loaded at 30 days, extend the cleaning interval to 60 or 90 days as appropriate. In no case should the filter cleaning interval exceed 90 days.

FILTER CLEANING

1. Leave the ozone generator ON.

2. Through the manway, slowly pull the filter module to the surface of the tank water, such that the top of the lift pipe is just below the surface of the water. Remove the Neoprene tubing from the 90 degree connector to stop the ozone flow to the diffuser. Now pull the entire filter module vertically through the manway in one smooth motion and place on the most level area of the tank. Do not pull up the filter so fast that turbulence will be created as this will knock excess debris off the filter. As you pull up on the filter, the lower flapper valve will open and release the water trapped inside the filter. This creates a slight vacuum inside the filter, thus helping to hold the debris on the pleats in place.

Note: Some debris will fall off the filter, but since this is coagulated debris, it will fall rapidly to the bottom of the tank.

3. Hose down the filter with a stiff water spray, washing from top to bottom. Remove the quick disconnects to gain access to the inside of the filter and hose from the inside out (reverse flow) for more thorough cleaning. Check to make sure that there is no debris in the flapper valve that would prevent sealing.

HELPFUL HINTS

You may wish to purchase a back up Filter Element. This will allow you to alternate between the current filter and a clean back up filter when needed. You then clean and store back up filter element in enough water to completely submerge. NOTE: Back up Filter Element must never be allowed to dry out.

A FREE Filter Cleaning Wand has been included with your PW 9000 system. This wand is engineered to ease the cleaning task and spray the filter from the inside out, cut cleaning time in half and save water at the same time. It is also handy for washing down driveways, windows, etc.

CLEANING & MAINTENANCE

IMPORTANT Follow these instructions to prevent possible equipment damage. HINT: Do not clean the filter too often as the filter performs better with a coating of particulates than it does when brand new.

1. DO NOT turn off your Generator. With system running, detach ozone tubing at barb connector at the tank manhole (interrupts ozone flow and stops bubbles).

2. Pull filter module slowly to surface of water. Using heavy gloves, pull filter module up and out of manhole in one smooth motion. Suggestion: Filter module can be lowered down the outside of smaller tanks so cleaning can be done at ground level.

3. Spin off the upper quick disconnect (QD). Remove handle/diffuser assembly from filter module. Do not remove from its tubing adapter or form tubing.

4. Do not soak the diffuser in Muriatic acid for a long period of time--rather dip up and down directly into the acid bottle (while holding on to tubing) for about 5 seconds and rinse with water spray. Repeat if required until the diffuser is white. **If hydrogen sulfide (rotten egg smell) is also a problem, soak diffuser in household bleach for 10-20 minutes and rinse (sulfur is not soluble in Muriatic acid).

5. Spin off lower quick disconnect; pick filter up and off of lift pipe. Remove top plate from filter. Using cleaning wand supplied with system, wash off debris from outside and then spray from inside to outside. Repeat of necessary. Filter staining is normal.

5. Spin off lower quick disconnect; pick filter up and off of lift pipe. Remove top plate from filter. Using cleaning wand supplied with system, wash off debris from outside and then spray from inside to outside. Repeat of necessary. Filter staining is normal.

6. Reassemble filter module. Spin lower quick disconnect down only until it stops. Attach and tighten handle assembly.

7. Lower filter module down into tank--it should sink readily. If it floats, it may be coated with calcium (hardness) and require soaking in a solution of 10 parts water to 1 part (10% solution) Muriatic acid for about 10-30 minutes or until the fizzing stops (a 30 gallon plastic trashcan is handy for this). Rinse well.

8. To attach ozone tubing at manhole and note bubble pattern of about 8-10 inches in diameter.

Read the Installation and Maintenance Manual supplied with your system. Replace the UV Assembly every 18 months to maintain correct ozone production level as the ozone out put will decrease over time.

PW9000 Ozone Treatment System

DIFFUSER CLEANING

The diffuser will become restricted over time due to the ozone precipitating out iron , manganese, calcium, etc., and plating the surface of the diffuser with these contaminants. A plugged diffuser will reduce both the ozone flow and therefore the water flow through the filter, thus impairing the ability of the system to maintain your water quality. A completely plugged diffuser can cause damage to the ozone generator.

During the filter cleaning, remove the handle assembly to gain access to the diffuser. Immerse the diffuser with Neoprene tubing attached in a gallon jug of swimming pool muriatic acid for about 30 seconds. Make sure the ozone hose has been disconnected from the 90 degree tubing connector as covered under filter cleaning, so no ozone gas is flowing through the diffuser, it will keep the acid from cleaning the diffuser pores and create excess acid fumes.

CAUTION: MURIATC ACID NEEDS TO BE HANDLED CAREFULLY. DO NOT BREATHE THE MURIATIC ACID FUMES.

Remove the diffuser form the muriatic acid and rinse completely with water. It should become sparkling white. Repeat cleaning procedure if necessary.

Replace the diffuser/handle assembly and tighten the quick disconnect. Slowly lower the filter module into the tank and reconnect the Neoprene tubing to the 90 degree connector.

Check for a rising pattern of bubbles in the tank and replace the manhole cover.

HIGH HYDROGEN SULFIDE WATER

(Rotten egg odor)

In water systems with very high hydrogen sulfide, the diffuser may become plugged with sulfur which is not soluble in muriatic acid. If this is the case, first clean the diffuser with muriatic acid as described above. Then rinse the diffuser thoroughly and soak for at least 15 minutes in concentrated chlorine solution and rinse.

ANNUAL MAINTENANCE

Once a year, the ozone hose from the generator to the mixer, and the ozone hose from the mixer to the filter module should be disconnected and condensation drained from the hoses.

BI-ANNUAL MAINTENANCE

The ozone generator`s UV light assembly should be replaced every 14 months to maintain peak ozone output. The ozone producing rays will decrease over time. This is due to the lamp gas "solarizing" and becoming more opaque to the ozone producing wavelength. Please note that the light you see coming from the UV view port on the front of the generator can is visible UV light. The wavelength of light that produces ozone is not visible to the human eye.

The ozone output of your system will reduce to about 80% of new after 12 months, 50-65% of new at 18 months and 25-40% of new at 2 years.

Ozone lamp replacement is especially critical when bacteria control is needed.

TROUBLE SHOOTING

Basic trouble-shooting of the system is quite simple. A decreased bubble pattern in the tank means there is less ozone flow and therefore less water flow through the filter, with the result being reduced water quality.

REDUCED OR NO OZONE BUBBLE PATTERN IN TANK:

1. Diffuser needs cleaning.

2. Check for ozone hose leaks with soapy water.

3. Bad air pump.

4. Leaking UV light assembly.

5. Crimped ozone hose.

6. Leaking 6 PSI check valve on mixer assembly.

The 6 PSI red check valve is the one between the 3/16 inch barb tee and the venturi (see figure 3A). If this valve leaks, some of the ozone gas will continuously bubble into the water feed pipe to the tank. To determine if the valve is leaking, place your ear against the venturi and listen for a "gurgling" sound. If the check valve is leaking, replace with new valve.

WATER CONDITIONS WERE GOOD, BUT THEN BECAME WORSE:

1. Filter needs cleaning.

2. Diffuser needs cleaning.

3. Reduced or no ozone bubbles in tank.

4. UV light assembly is more than 14 months old.

5. Large water usage such as filling swimming pool or irrigation.

6. Check the filter module flapper valve, located on the bottom of the filter module, for foreign objects (leaf, twig, etc.) that may be keeping the flapper valve from sealing.

HELPFUL INFORMATION

Once your holding tank has stabilized, you will start enjoying good water. If you have been living with poor water in your home for some time, it is very likely that your plumbing has accumulated deposits of the contaminants that are now being removed from your water supply. These deposits will be removed from your plumbing over time:

Iron: As your pipes are cleaned out, you may notice "spurts" of iron colored water when your taps are first opened. This is especially true for taps that are not used regularly. Cleaning out your toilet tanks will remove any accumulated iron and help eliminate continued toilet staining.

Odor/Taste: These problems are similar to iron in that you may notice "spurts" of bad taste or odor when a water tap is first opened.

Calcium/Hardness: Your new PW 9000 Ozone Treatment System, through the use of ozone/polarization technology, will make your water appear softer. Your water will suds and act like soft water without any sodium being added. You may still notice some hard water deposits on your fixtures, but these deposits can be more readily removed because they will not bond strongly. For extremely hard water, you may wish to treat your water with an available water softener.

EXTENDED WARRANTY

A three year factory extended warranty is available at additional cost through American Tank CO. This warranty covers all components of the system (except filter), and extends the factory warranty for an additional two years beyond the original one year warranty. This extended warranty includes two replacement UV lamp assemblies, one for replacement at 14 months and one for replacement at 28 months. Contact your Sales Representative for details.

WARRANTY

American Tank Co. warrants to the original owner it`s treatment system Model PW 9000 to be free from defects in material and workmanship for a period of 1 year from the original date of purchase, so long as the water treatment system has been installed in accordance with the installation instructions.

To get a defective part replaced, call your Sales Representative and explain the problem.

1. Have American Tank Co. service the unit at a nominal labor charge which are responsible to pay.

2. You may obtain your defective part replacement from American Tank Co. by shipping the part to us, UPS prepaid, along with completed Warranty Claim Form. American Tank Co. will repair or replace the failed part and ship via UPS collect within 3 days after receipt of the defective part.

As the owner`s exclusive remedy, any defective part or assembly will be repaired or replaced at the sole discretion of American Tank Co., Field service labor is specifically excluded from the terms of this warranty.

Except as set forth above, there shall be no other guarantees, warranty or liability either expressed, implied, oral or statutory and in no event shall American Tank Co., its agents or employees, be liable for injury or damage to any person or property whatsoever, or for any special, indirect, contingent, secondary or consequential damage of any nature however so arising. American Tank Co. does not warrant the PW 9000 Ozone Treatment System to be merchantable or fit for a particular use.

Your specific legal rights under this limited warranty may vary from state to state.